Energy savings through demand-controlled ventilation

For several years now, SYSTEM C+® by RENSON® has been a very successful ventilation system thanks to its simplicity, ease of maintenance and energy efficiency.

Now however, we have the new Healthbox® II which includes new innovative technology. SmartZone technology ensures that the house is optimally ventilated, according to the resident’s activities. The new TouchDisplay allows the residents to control their own personalised ventilation program whilst measuring and displaying indoor air quality. This ventilation system can help homes reduce their energy consumption whilst creating a healthy indoor environment.

Read on to find out how the new Healthbox® II makes energy saving and a healthy indoor environment possible!

Thanks to SmartZone technology you can have ventilation controlled within the rooms that you are most present.

Summary

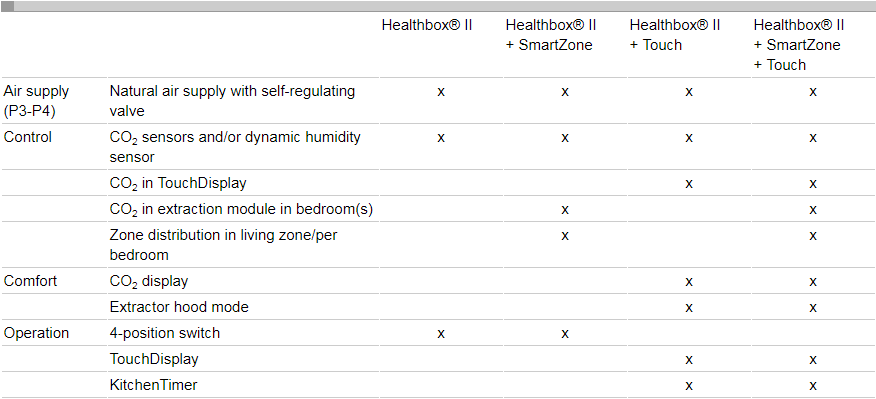

The following table summarises the different configurations available.

Mechanical ventilation system configuration tabel – Renson

The Healthbox® II has up to 6 separate connections to enable energy-efficient ventilation.

Design vents for extraction

In order to enable the integration of the extraction vents into the ceiling, the location of the control system was shifted from the extraction vent to the electronic control modules on the motor unit.

In addition, the plastic extraction vents were replaced by aluminium design vents. These design vents (height 11mm) were developed for integration or mounting into or onto the ceiling (or wall), for a plaster, plasterboard or a MDF base surface. These vents are generally supplied in RAL 9010 matt (white) but can easily be painted over. The occupant can choose between 6 different designs, so that combinations with all kinds of décors are possible.

The vents are generally equipped with an 80 mm diameter connection, while only for the kitchen, this standard diameter is 125 mm.

Renson Healthbox roosters

Unique automatic calibration system

The entire system is automatically calibrated, achieving the appropriate flow rate for each control module, regardless of the length and type of the ducting. The control modules can be programmed according to the type of room and/or standard, which is to say, one can indicate at the time of installation, whether the room in question is a wet or dry room. The control modules will then be set to the required maximum flow rate per room and will communicate with the motor unit in order to determine the required total flow rate of all wet and dry rooms, specifically for that house.

This avoids the risk of possible errors during settings and is a major timesaver. The total adjustment time will be limited to an average of 12 minutes.

Energy savings through optimised, extraction, on-demand

The Healthbox® II has a powerful motor with control modules that can ensure proper ventilation of any connected room at all times. A humidity and/or CO2 sensor in each control module measures the extraction air 24 hours a day, and communicates with the central processor. The control module limits the extraction rate per room if possible and also runs the motor at a lower speed.

The Healthbox® II thereby achieves heat savings and savings in electricity consumption.

4-position button (XVK4)

The four-position switch is a wired button that provides feedback about the status of the ventilation group via blue LEDs. The button allows us to make a selection from 4 programs:

Intelligent ventilation, wherever you happen to be !

Thanks to SmartZone technology you can have ventilation controlled within the rooms that you are most present.

During the day, ventilation will be mainly in the living rooms.

During the night, ventilation is mainly required in the bedrooms

Measuring indoor air quality

The presence of people, computers, printers and other devices leads to indoor air pollution, which can, among other things, be seen in the high ppm (parts per million) of carbon dioxide values. The carbon dioxide level is a recognised parameter for indoor air quality and is often the unexpected cause of many health problems.

Customisable program

Option of connecting a motorless extraction hood to your ventilation system. The kitchen module can be activated using the TouchDisplay and/or KitchenTimer. When switching to the cooking mode, the ventilation system can use its full extraction capacity in the kitchen, while the airflow in the other rooms remains at a minimum level. If the kitchen mode is not used, your extractor hood will provide the basic ventilation (basic ventilation 12-75 m3/h – 250m3 cooking function/h).

KitchenTimer

This specially designed kitchen operation makes it possible to regulate a separate control module, which controls the motorless extractor hood.

Your guarantee on airflow, sound & air tightness

Easyflex is a semi-rigid, corrugated air duct made out of polyethylene with an external diameter of 140x64mm and an equivalent inner diameter of 90mm. The smooth inner surface of the double walled air duct is treated with antistatic and antibacterial additives to prevent dust accumulation and bacteria outbreaks.

Thanks to its size, an airflow of 57m³/h is achieved at a design speed of 2,5 m/s. A high airflow combined with a low air speed guarantees a silent air duct system.

The limited height of the Easyflex air duct allows it to be installed easily into false walls/ceilings, in concrete or screed.

Easyflex is a semi-rigid, corrugated air duct made out of polyethylene with an external diameter of 140x64mm and an equivalent inner diameter of 90mm. The smooth inner surface of the double walled air duct is treated with antistatic and antibacterial additives to prevent dust accumulation and bacteria outbreaks.

Thanks to its size, an airflow of 57m³/h is achieved at a design speed of 2,5 m/s. A high airflow combined with a low air speed guarantees a silent air duct system.

The limited height of the Easyflex air duct allows it to be installed easily into false walls/ceilings, in concrete or screed.

- Documentation System C+® Evo II – Healthbox® II

- Technical documentation – Healthbox® II

- CIBSE: Performance of a demand controlled mechanical extract ventilation system for dwellings

- Touch display software v2.x.0

- Touch display software v3.0.1

- Connect Ventilator unit to a Domotics-system

- Easyflex air duct

- Healthbox II Breeze – description

- Healthbox II Breeze – neutral specification

- Healthbox II compact Breeze – neutral specification